An air handling unit, commonly called an AHU, is the composition of elements mounted in large, accessible box-shaped units called modules, which house the appropriate ventilation requirements for purifying, air-conditioning or renewing the indoor air in a building or premises.

They are usually installed on the roof of buildings and, through ducts, the air is circulated to reach each of the rooms in the building in question.

Main functions of an AHU

In addition to managing the proper ventilation of the interior with outside air, the AHU performs other functions:

- Filtration and control of the quality of the air that will reach the interior, thanks to the air purification filters, and depending on the retention of these filters, the air will be clean.

- Control of the air temperature that regulates the air conditioning system in cold or hot, so that the thermal sensation in the interior is the desired one.

- Relative humidity monitoring for greater indoor comfort.

For its part, the places for which the AHU is intended are those in which the flow of people is very large and accumulates many people at the same time and whose natural ventilation is limited: hotel dining rooms, function rooms, restaurants, convention halls… It is also a suitable option for those spaces with very high hygiene requirements: laboratories, clean rooms or operating theatres, among others. An AHU can also be used to ventilate places where air conditioning is provided by radiators or underfloor heating, for example.

What does an AHU consist of?

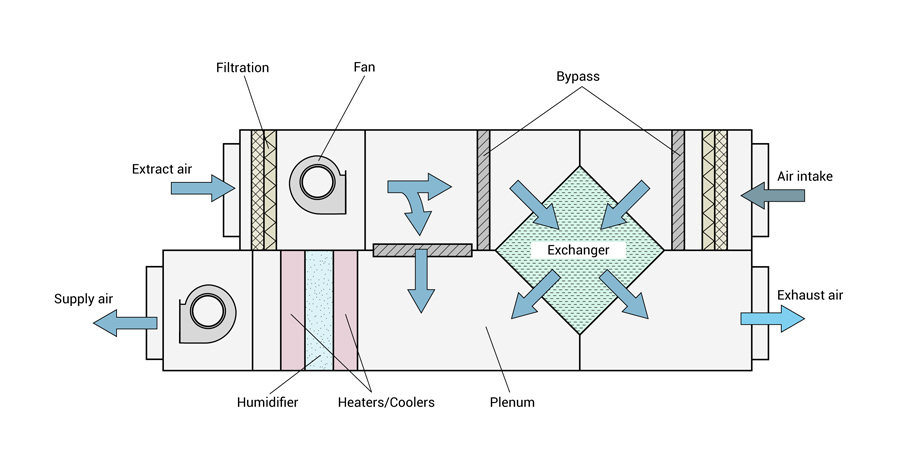

- Air intake: air handling units collect air from outside, which is treated and distributed throughout the rooms; and/or indoor air that is “recycled”.

- Filter: depending on the air purity requirements, the filter applied will have a higher or lower particle, viruses, bacteria, odours, and other air pollutants retention.

- Fan: this is an electromechanical system that powers the air to expel it from the AHU to the ducts that distribute the air throughout the rooms.

- Heat exchangers: devices that transfer temperature between two fluids, in this case, coolant and air, separated by a solid barrier.

- Cooling coil: the air passing through this module is cooled. In this process, water droplets can be generated, which are collected in a condensate tray thanks to the built-in droplet separator.

- Silencer: coatings that considerably reduce the sound level of the installation.

- Plenums: empty spaces in which the air flow is homogenised.

Energy efficiency of AHUs

The ultimate aim of an air handling unit is energy efficiency and this is mandatory since 2016 by the European Ecodesign Regulation 1235/2014.

By having heat recovery units, the AHU reduces the use of energy required in air conditioning, as in the exchanger, the indoor and outdoor air is mixed, so that when the air reaches the coil the temperature contrast is lower, therefore, the climatic contribution is also lower and energy consumption is also reduced.

Likewise, the variable regulation of the equipment means that the fans can work according to the flow rate needs, reducing their consumption.

Modular operation theater manufacturer mumbai| Modular operation theater manufacturer mumbai| Clean room air tight door manufacturer in india| Clean room air tight door manufacturer in india| Operation theater classified door in Mumbai| Modular operation theatre manufacturer Gujarat| Operation theater classified door in Mumbai| Pharmaceutical clean room manufacturer in hyderabad| Clean room manufacturer in madhya pradesh| SS modular operation theatre in india| Dr surgeon control panel INDORE mp| Hygienic air handling unit in Mumbai| Clean room manufacturer in Mumbai| Dr surgeon control panel Mumbai| Pharmaceutical clean room manufacturer in Gujarat| SS modular operation theatre in mumbai| Clean room panel manufacturer in india| ivf lab manufacturer indore mp| Hygienic air handling AHU units in india| Modular operation theater manufacturer in Kalyan| ivf lab manufacturer in Thane| Pharmaceutical clean room manufacturer in Pune| Dr surgeon control panel in Mumbai| Operation theater classified door in Nasik RoDr surgeon control paad| Hygienic air handling units in Bandra| Hygienic air handling units in Bandra| SS modular operation theatre in Kolhapur| Modular operation theater manufacturer in Bhandara Road.| ivf lab manufacturer in Borivali| Pharmaceutical clean room manufacturer in Vasai Road| Dr surgeon control panel in Dadar (Central)| Operation theater classified door in Andheri| Hygienic air handling units in Virar| Clean room manufacturer in Nalla Sopara| SS modular operation theatre in Surat| Modular operation theater manufacturer in Ahmedabad| ivf lab manufacturer in Vadodara| Pharmaceutical clean room manufacturer in Navsari| Dr surgeon control panel in Rajkot| Operation theater classified door in Kosamba| Hygienic air handling units in Mahemdavad| Clean room manufacturer in Dwarka| SS modular operation theatre in Godhra| Modular operation theater manufacturer in Disa| ivf lab manufacturer in Halvad| Pharmaceutical clean room manufacturer in Sabarmati| Dr surgeon control panel in Paddhari| Operation theater classified door in Vani Road| Hygienic air handling units in Indore| Clean room manufacturer in Bhopal [Bhopal]